2402 Spring Ridge Drive

Unit C

Spring Grove, IL 60081 Phone: (815) 675-0060 Fax: (815) 675-3118

Unit C

Spring Grove, IL 60081 Phone: (815) 675-0060 Fax: (815) 675-3118

Specialists in molded plastics for the electronics & electromechanical industry

Mold Design

Injection Molding

- Precision Plastic Injection Molding

- Short & Long Production Runs

- In House Tooling

- Customer Specified Materials

- Custom Colors

Precision CNC Components

- Latest CAD design & engineering

- CNC Milling & Grinding

- CNC Engraving

- Polishing

Design Services

- In-House Mold Design

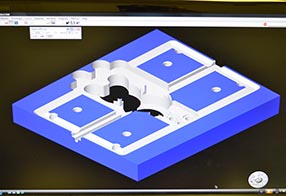

- CAD Layout

- Gibbs-Cam CAD/CAM

All of the submitted designs we receive are formatted using GibbsCAM Software. Gibbs software is state-of-the-art, and allows our designers and tool makers to create the best tool design for your injection molds. This technology enables us to convert images into 3D pictures and quickly translate your design into a plastic mold, and soon after a custom plastic molded part.

GibbsCAM Software provides numerous benefits to our customers. Human error is virtually eliminated in the maching process which means production will be quicker and more efficient. This softwares ease of use will assist in rapid manufacture of your molded component tooling.