2402 Spring Ridge Drive

Unit C

Spring Grove, IL 60081 Phone: (815) 675-0060 Fax: (815) 675-3118

Unit C

Spring Grove, IL 60081 Phone: (815) 675-0060 Fax: (815) 675-3118

Specialists in molded plastics for the electronics & electromechanical industry

Insert Molding Services

Injection Molding

- Precision Plastic Injection Molding

- Short & Long Production Runs

- In House Tooling

- Customer Specified Materials

- Custom Colors

Precision CNC Components

- Latest CAD design & engineering

- CNC Milling & Grinding

- CNC Engraving

- Polishing

Design Services

- In-House Mold Design

- CAD Layout

- Gibbs-Cam CAD/CAM

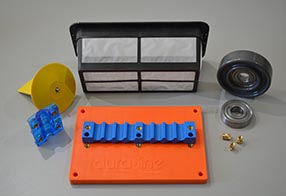

Insert molding is a common type of injection molding process used to combine plastic and another object

( ceramic, metal, plastic) into one component. First inserts are placed in the mold, then molten plastic is injected into it and allowed to harden. After the plastic is cooled, the part is ejected out with the inserts and plastic forming one piece. The

finished part produces a securely fused component.

Benefits of insert molding

- Cost reduction by reducing the need for secondary finishing

- Ease in assembly

- Product consistency

- Increased flexibility for more complex shapes and components

- Repeatable high tolerance

- Higher strength and durability